Facts About Mhs - Material Handling Supply Inc. Revealed

Facts About Mhs - Material Handling Supply Inc. Revealed

Blog Article

What Does Mhs - Material Handling Supply Inc. Mean?

Table of ContentsNot known Facts About Mhs - Material Handling Supply Inc.Little Known Questions About Mhs - Material Handling Supply Inc..Everything about Mhs - Material Handling Supply Inc.The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is DiscussingThe Buzz on Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. for DummiesLittle Known Facts About Mhs - Material Handling Supply Inc..The Single Strategy To Use For Mhs - Material Handling Supply Inc.

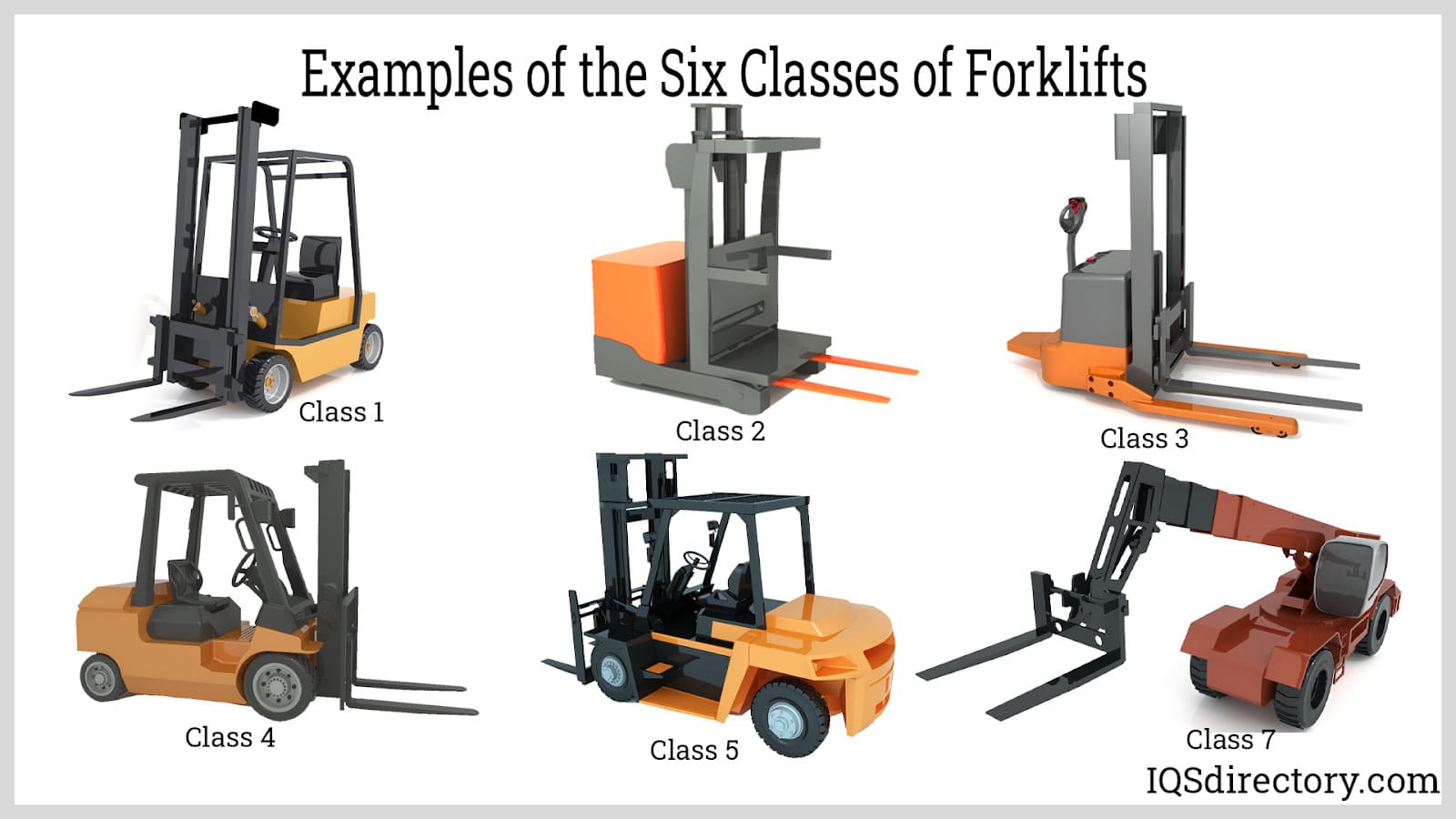

Rather, they are made use of to increase lots just sufficient to allow horizontal motion. Powered by an electrical engine, low-lift trucks ought to constantly have the lots face uphill. They need to also drive in reverse when going down ramps. There are two different kinds of forklift trucks in this team: straight-mast and extended-reach.Powered by diesel, RTFLs offer a secure means to take a trip with lots on irregular ground. These forklifts are used for relocating and piling ISO conventional containers for the shipping market. They can raise to 60 loads at low rates. This coincides as two complete containers. Straddle trucks can pile containers even more than 13 ft.

Drivers sit on top of the truck so they can see in front and behind them. These vehicles also come in mini versions to move containers around yards and depots. These forklifts are used to handle lumber, steel bars, pipes, and other lengthy products. Unlike various other forklifts, they do not have front uprights that can hinder of packing and unloading.

All About Mhs - Material Handling Supply Inc.

They are installed onto vehicles to boost the loading and dumping process. Many forklifts have a three-point shock absorber that contains 2 front wheels and a pivot factor at the back axle. Together, these points produce a "security triangle" that decreases the danger that a lift will certainly tip over, also on high or rugged surface.

If the lift is moving on or backward or parked on a slope, its center of gravity changes. In this instance, the forklift's facility of gravity falls outside the security triangle. The result: the lift will tip over. A forklift's facility of gravity moves any type of time a lift operator increases, brakes, or transforms.

The Definitive Guide for Mhs - Material Handling Supply Inc.

Recognizing what are the various kinds of forklifts is just the start. https://moz.com/community/q/user/mhsinc30677. Prior to you can operate any forklift, you should be properly trained to do so. This isn't simply a recommendation: it's the legislation. Companies are called for to give OSHA-approved training to their workers at no charge. This training procedure ought to encompass all various forklift types used in your organization

Forklifts are ranked for loads at a specified maximum weight and a defined onward center of mass. Makers step and test forklifts and designate these specifications to secure operators from accidents and rollovers. The majority of warehouse forklifts have lots capacities in between one and 5 lots. Some larger forklifts can raise to 50 heaps (these are suggested for heavier commercial applications such as delivering containers).

Indicators on Mhs - Material Handling Supply Inc. You Should Know

In the United States, Occupational Security and Health And Wellness Management (OSHA) regulates the use of powered forklifts and mandates drivers must be at least 18 years old. Most forklifts have a power resource to do the hefty lifting and maneuvering.

Propane is typical, cheap and burns clean. LPG forklifts can be used inside your home since they run quietly and do not launch high amounts of unsafe discharges. LPG containers are commonly placed on the back of the vehicle and are created to make it possible for fast altering. Diesel: Diesel forklifts supply even more power and lift ability than LP forklifts, and they are better matched for exterior applications due to the fact that diesel exhausts call for consistent air flow.

The Only Guide for Mhs - Material Handling Supply Inc.

Harsh surface forklifts are developed for outside use on irregular surfaces - forklift dealer watkinsville, ga. Some harsh surface forklifts have stabilizers to provide extra stability assistance.

The Definitive Guide for Mhs - Material Handling Supply Inc.

Pallet jacks are the simplest and a lot of basic forklift layout featuring two forks generally 20 1/4 inches or 27 inches vast. Their basic feature is limited to relocating pallets inside a storehouse. Pallet jacks normally have guiding wheels in the front, and each fork has either a single wheel or more bogie wheels.

Many pallet jacks are developed to manage around 5,000 pounds on standard, and some versions are able to raise up to 8,000 pounds. There are 3 common kinds of pallet jacks: Hands-on pallet jacks are hand-powered by the operator and utilized to lift, reduced, and steer pallets from one place to another.

An Unbiased View of Mhs - Material Handling Supply Inc.

They are commonly utilized in retail and warehousing operations - Forklift dealer athens, ga. Powered pallet jacks (likewise called electrical pallet vehicles walkies and power jacks) are comparable to hands-on pallet jacks in style, however, they include an engine that allows lifting and moving of much heavier and stacked pallets. Some powered pallet jacks include a system for the operator to stand upon while utilizing it

They feature sturdy frameworks and pneumatic tires to accommodate a wider range of surface area types. Walkie stackers are another simple design featuring a pole that makes it possible for lifting payloads to higher heights than pallet jacks. Walkie stackers are commonly claimed to be a blend of a pallet jack and forklift - due to the fact that they have an easy layout and take care of (comparable to a pallet jack) while giving reach (similar to a forklift).

Operators generally overview and steer the walkie stacker around the storage facility by drawing the take care of. Many walkie stackers are developed to manage in between 2,000 and 3,000 lbs generally, with some designs raising to 4,000 lbs go now (forklift rental near me). Raise elevations vary based upon make and design and generally vary between 6 and 14 feet

Mhs - Material Handling Supply Inc. Fundamentals Explained

Report this page